Welcome to Samkit Imaging Systems Private Limited!

Special Coated Papers

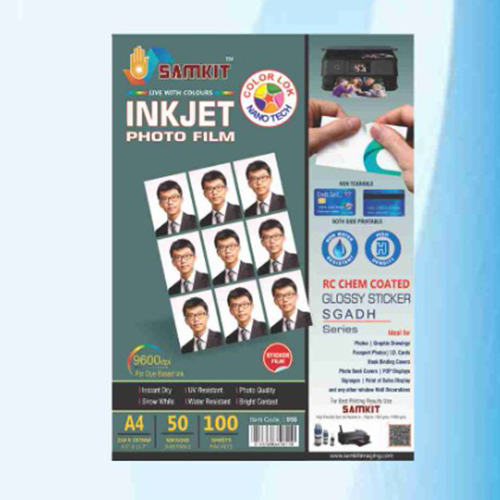

Product Details:

- Harness Soft to medium

- Standard ISO 9706

- Style Gloss, Matte, Textured

- Thickness 100-250 gsm

- Size A4, A3, SRA3, Rolls, Customized

- Usage Professional & Commercial

- Length Standard roll & sheet lengths

- Click to View more

X

Special Coated Papers Product Specifications

- Special Coated Paper

- 100-250 gsm

- Wood pulp, Chemical pulp with special coating

- Gloss, Matte, Textured

- Printing, Packaging, Labeling, Wrapping

- Custom sizes available

- Soft to medium

- ISO 9706

- Standard roll & sheet lengths

- Professional & Commercial

- Various, typically 90-300 gsm

- A4, A3, SRA3, Rolls, Customized

- White, Off-white, Cream, Custom shades

Product Description

Range of Special Coated Papers:

- White Maplitho Paper Labels

- White Matte Coated Paper Labels

- White C.C. Glossy Coated Paper Labels

- Lustre, Holographic, Metallic Paper Labels

Face 70,90, 100 Gsm

Release 60,90,120 Gsm

Available Sizes: 4R, A4, A3, 12"x 19", 13"x 19"

100 Sheets Pack Continuous Rolls of 24", 36", 42"

Also Available Prepunced Labels 1 Ups to 84 Ups

Features

- Instant Dry

- High Gloss

- Vivid & Sharp Color Print

- Bright Contrast

- Water Resistant

- Ultra White

Superior Quality and Versatility

Our special coated papers are crafted from premium wood and chemical pulp with a unique coating, resulting in high brightness (>92% ISO) and excellent opacity. The collection covers a range of finishes-including gloss, matte, and satin-providing versatility for different professional and commercial applications like packaging, labeling, and high-impact printing.

Designed for Performance and Sustainability

Each sheet is pH neutral and recyclable, ensuring it is both acid-free and eco-friendly. Enhanced moisture resistance and robust coating (available on one or both sides) mean these papers stand up to demanding environments while reliably preserving prints and packaging. Supported by ISO 9706, they maintain integrity and color over time.

FAQ's of Special Coated Papers:

Q: How are special coated papers with high opacity and neutral pH beneficial for printing applications?

A: These characteristics ensure outstanding print clarity and color vibrancy while preventing ink bleed-through. The neutral pH (acid-free) helps protect prints from yellowing or degradation, making them suitable for archival and professional use.Q: What types of finishes and sizes are available for these coated papers?

A: You can choose from glossy, matte, and satin finishes. Standard sizes include A4, A3, SRA3, rolls, and custom dimensions. Both grain directions and various thicknesses (100-250 gsm) are available to meet specific printing or packaging needs.Q: When should I choose single-side versus double-side coated paper?

A: Single-side coated papers are ideal for projects needing print only on one surface, such as labels or certain packaging, while double-side coated papers are preferred for items like brochures or double-sided prints that require consistent quality on both sides.Q: Where are these papers manufactured and supplied from?

A: Our special coated papers are produced in India, utilizing modern manufacturing processes to ensure consistent quality. They are available for supply across domestic and international markets.Q: What is the process for ensuring moisture resistance and surface smoothness?

A: The papers undergo advanced coating treatments that impart a premium smooth feel and create an effective moisture barrier. This process not only enhances print compatibility but also improves the durability of the finished product.Q: How can these papers be recycled and what makes them environmentally responsible?

A: Made with recyclable materials and following ISO 9706 standards, these papers can be easily recycled after use. The neutral pH and responsible sourcing of pulp further contribute to their environmental benefits.Q: What is the typical lead time and packaging method for bulk orders?

A: Depending on order size, lead time ranges from 7 to 15 days. The papers are packed either ream wrapped or in bulk, ensuring they remain protected during transportation and storage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free